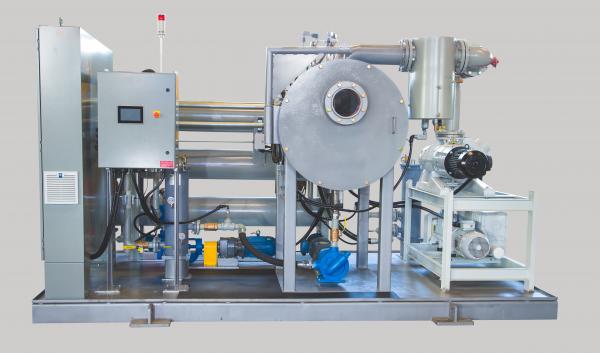

The Transformer Oil Purifier / Filtration System

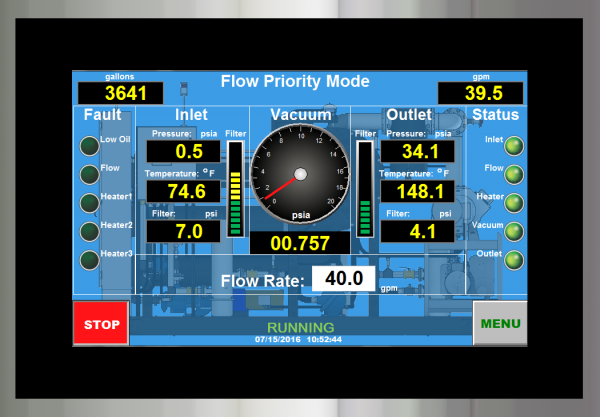

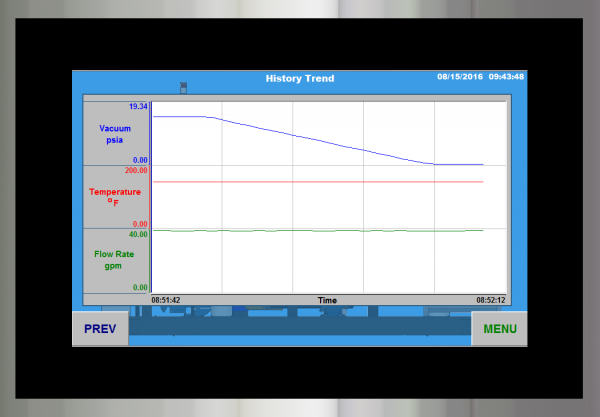

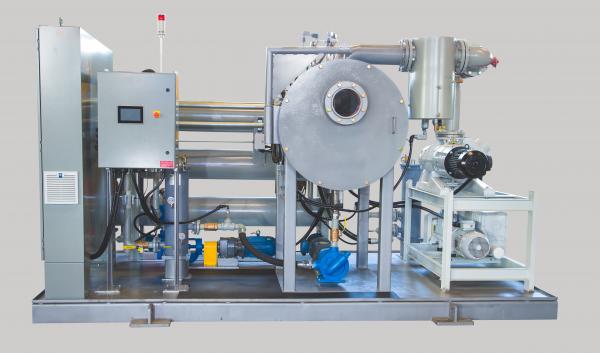

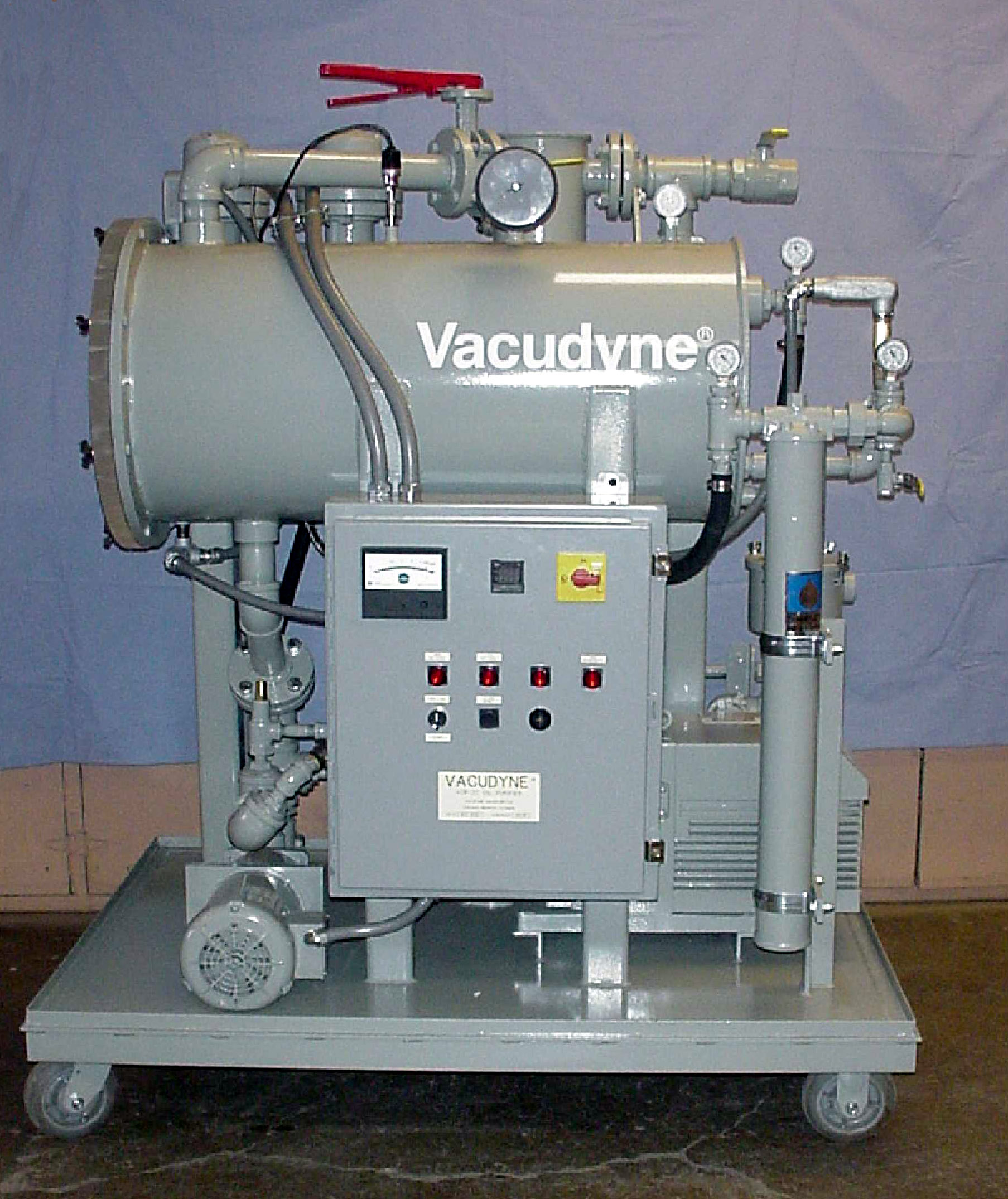

removes impurities and restores / improves the electrical, chemical and physical properties of transformer insulating oils. This oil is an integral part of most large power transformers. It serves two major roles, as a cooling agent and as an electrical insulator between internal components. Contamination of this oil compromises the insulating properties and leads to premature failure of the transformer. This contamination can be in the form of water, dissolved gases, or foreign particles. By processing this oil with a vacuum dehydration unit like the Vacudyne Transformer Oil Purifier, this contamination can be removed returning the insulating oil to it’s original specifications. The system incorporates high vacuum and mechanical filtration to dehydration, degasification and filter contaminated oil. Engineered with functionality and versatility to meet a wide range of applications with features such as: an inlet pump capable of drawing oil from long distances and low elevations, a unique multi-level vacuum chamber design for rapid degasification, a sophisticated heating control scheme to insure safe and efficient processing of the contaminated oil, and a variable speed outlet pump to return the processed oil to the transformer being serviced. Control, monitoring, and user interaction is accomplished through an industrial grade touchscreen operator interface. All parameters are easily viewed and adjusted through this interface along with viewing of current and historical data.

Overview

The Vacudyne Transformer Oil Purifier removes impurities and restores / improves the electrical, chemical and physical properties of transformer insulating oils.

Models Includes:

- NG Oil Purifier System (High Water Content)

- VOP-ST - 70 gph capacity

- VOP-1T - 100 gph capacity

- VOP-3T - 300 gph capacity

- VOP-6T - 600 gph capacity

- VOP-12T - 1200 gph capacity

- VOP-18T - 1800 gph capacity

- VOP-24T - 2400 gph capacity

- VOP-30T - 3000 gph capacity

- VOP-40T - 4000 gph capacity

Features

Models Typically include:

- Vacudyne's unique multi level vacuum chamber design

- Automated control system for ease of use and unattended operation

- Intuitive display of vacuum, pressure, temperature and filter conditions

- Easy access to all operating parameters

- Built-in logging buffer for historical informaiton retrieval

- Electronic flow meter with lifetime and user resettable displays

- VFD pump drives

- Oil level control including high and low oil level safety shutdown

- Multi-stage foam control for optimal processing

- TEFC motors

- Oil pump with single mechanical seals

- Low watt density heaters to aid in water removal

- NEMA 12 control and power cabinets

- Inlet and outlet filters for particulate removal

- Booster / backer vacuum pump to ensure a deep consistent vacuum

- Thermostatically controlled heater with selectable capacity

- Heavy duty rigid steel construction for long lasting durability

- Oil retentive skid design for spill containment

Applications

- Transformer Insulating Oil

- Switchgear Insulating Oil

- Load Tap Changer Insulating Oil

- Other liquid applications requiring the removal of impurities and restoration

Specifications

Water Removal: 100 ppm to < 5 ppm by ASTM method D1533

Total Gas Content: 12% to < 0.25% by volume by ASTM method D2945

Particulate Removal: Filters 99% of particulates ≥ 0.5 microns

Dielectric Strength: Restores the oil dielecric strength to manufacturer's original specification by ASTM method D1816